Both passive and active RFID are used frequently in real-time location systems (RTLS). While they are used to perform a similar function, they use very different technologies.

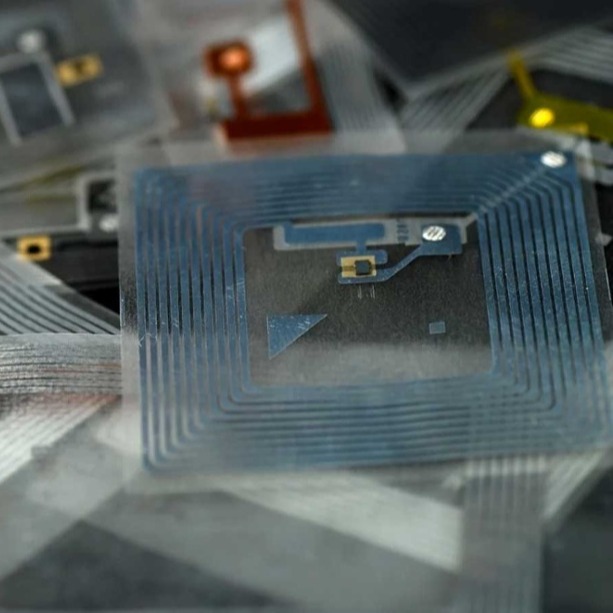

Passive RFID systems use a high-power, low-frequency actuator to radiate energy toward a tag. The tag absorbs the energy and radiates back a coded message to the actuator at a higher frequency and lower power.

The primary advantage of passive RFID systems is that tags are very inexpensive, ranging from $0.10 to $1.50 per tag. These tags also don’t require batteries, so they last for many years. The disadvantage of passive RFID is that the infrastructure is expensive and can only detect the “presence” of a tag, not its exact location.

Active RFID systems, on the other hand, use battery-powered tags that beacon or connect to various access point readers throughout an area (like a building) and transfer data to the server or cloud. Active RFID tags (like Bluetooth or ultra-wideband), are more expensive ($10+) but have the advantage of using a much less costly infrastructure of readers.

Thus, the real tradeoffs between these two types of technology are 1) the shifting of costs from tags to infrastructure, and 2) trading complexity and accuracy for lower total system costs.

Depending on the type of RFID system you're planning to implement, the costs you incur will vary. Here’s a breakdown of seven RFID costs so you can be prepared before you select and integrate a specific type of technology:

1. Equipment Costs

If you choose a passive RFID system, you'll need to consider the RFID reader cost, in addition to the costs of cabling and antennas. For example, an Impinj Speedway reader could run around $1,500, and when additional reader and cabling costs are considered, your passive RFID system could total $3,000 per reader in a manufacturing setting.

To get the location granularity you require, you’ll likely need a dense network of these readers, so be sure to budget accordingly. Keep in mind that you also typically have to run power over Ethernet (POE) to passive RFID devices, which can add to your equipment costs.

In a typical manufacturing setting, RFID readers are needed at all entries and exits, as well as in common material storage areas. If a tagged item is placed in an area where readers are not present, the item cannot be located. The location could possibly be inferred by the last seen entry/exit event or by manually “hunting” for the tag using a handheld reader. The use of handheld inventory “guns” is especially common in Aerospace RFID.

The equipment needed for active RFID is significantly less expensive (roughly 10 times less) than the equipment for passive RFID, as the reader equipment isn't as powerful or technologically sophisticated. While ultra-wideband (UWB) systems can be even more costly than passive RFID, they have the advantage of incredibly accurate positioning, generally down to a few centimeters.

A standard Bluetooth-based active RFID system can have varying levels of accuracy. The AirFinder system uses a hybrid approach, where location beacons are placed in areas to aid in the accuracy that can be achieved over standard active RFID alone.

2. Installation Costs

Passive RFID installation must be done by an expert who is well versed in tuning the equipment, directing the antennas, running the necessary connectivity tests, and configuring settings and networking details. The readers are generally connected via a LAN network to a central server, which is typically on site and processes all of the RFID data.

Specialized antennas are used for passive RFID and must be installed and calibrated to ensure appropriate performance. For these reasons, the installation costs of passive RFID are significant.

On the other hand, many active RFID systems like AirFinder can be installed by a member of your IT team in as little as one day, making the process simpler and much less cost-prohibitive. Generally, the exact placement of an active reader is not important; you can position it wherever it’s most convenient, negating the cost of having to rework your facility. However, ultra-wideband active RFID systems have installation costs that can exceed even those of passive RFID.

The ongoing maintenance costs associated with both systems are about the same. These costs mainly address issues with equipment that gets unplugged or goes offline for some other reason. Because passive RFID systems have larger standalone antennas, they are more prone to damage in busy industrial settings, so your facility may require some modification to accommodate the hardware.

3. Tag Costs

One of the primary benefits of passive RFID is the low cost of tags, which usually run for much less than a dollar. One exception is if you need to tag a metal object, in which case the tags will be slightly more expensive because regular passive RFID tags won't perform appropriately. There are other highly specialized RFID tags for laundry or autoclaves that can run even higher.

Tags are one of the few items that cost more for active RFID. While RF beaconing-style active RFID tags are still less expensive than the tags used for alternative technologies like Wi-Fi and ultra-wideband, you can expect to pay up to (or more than) 100 times as much for an active RFID tag as for a passive RFID tag, between $5 and $15 each.

In addition, active RFID tags can be coupled with wide-area technology like cellular and GPS to provide seamless indoor/outdoor locating and tracking, so they may very well be worth the additional cost for your application.

Another cost factor for active tags is the cost of maintaining the batteries. Some systems have disposable tags, while others make it possible to replace batteries. Either way, the battery life cycle costs and associated labor must be considered when calculating the overall system costs for an active RTLS system.

4. Software Costs

Passive and active RFID readings are useless without asset management software—and this kind of software can run you a pretty penny. You can learn more about the capabilities to look for in real-time location system (RTLS) software.

Generally, the complexity and specialization of the software drive the cost. A basic tag reading software could be an open-source project, whereas an integrated RFID to ERP enterprise application could cost hundreds of thousands of dollars to maintain.

Many active RTLS systems like AirFinder use a cloud SaaS model, where the software is bundled together with the costs of other parts of the system.

5. Ongoing License Costs

While active RFID licensing costs are typically bundled with the software, passive RFID technologies often require ongoing licensing costs that go toward support and software upgrades. These can be quite expensive, so be sure to account for this cost before you select a passive RFID technology.

These license charges are especially common for Wi-Fi-based RTLS systems where the location technology is an add-on to existing Wi-Fi access points. Cisco Meraki is an example of a Wi-Fi-based active RTLS system that has an ongoing license fee.

6. Maintenance Costs

As mentioned above, passive readers are more complex than active readers due to their extensive cabling, antennas, etc. And because the passive readers are fairly large, they’re at a greater risk of being snagged or bumped, which could lead to costly maintenance issues over time.

Active RFID systems are less complex, but their tags do include batteries. This means the tags will need to be maintained anywhere from a few months to every few years, depending on their life expectancy.

Training is another aspect of the ongoing system maintenance that some customers don’t consider. For an RTLS system deployment to be successful, all staff need to be trained initially and on an ongoing basis to fully realize the return on investment for such a system.

7. Integrator Costs

If you choose to purchase an active or passive RFID solution from an integrator, you’ll likely pay a premium over what you would pay if you were to go directly to the technology solution provider. That said, integrators often have teams of experts available to help you select the best technology to fit your problem, which could make the additional expense worth it.

Some RTLS technology companies provide their own installation, design, and support services for their equipment. AirFinder often bundles these services into its ongoing system costs.

It would be wrong to say that active or passive RFID RTLS systems are more appropriate for a customer based solely on cost considerations. Often, both systems can cost nearly the same when you consider all of the aspects discussed above. You need to strike a balance between system capabilities, location accuracy, number of tags, and ongoing maintenance and support to make the most of your investment.

Large enterprises—or companies with complex use cases—may choose standalone asset tracking software to run a number of tracking and sensing solutions. But many organizations looking for tracking technology are more interested in purchasing a full-stack RTLS solution. If you choose an end-to-end solution, you won’t have to deal with the hassle of integrating the hardware and software.

Learn more about one cost-effective, proven active RFID solution.

If you would like some additional information about AirFinder, and how other organizations have saved on the cost of RFID RTLS systems, feel free to contact us. We’ll be happy to help you during your research and planning.